ZHAFIR ZERES F SERIES Packaging range

OUR ENERGY SAVING HYBRID – ELECTRIC MACHINE WITH IN-BUILT HYDRAULICS

Fast, Electric, Flexible and Efficient

The packaging market is diverse. There is no such thing as “the” packaging specification, which is why the requirements for packaging are just as diverse as the enormous range of different goods and products in terms of size, weight, texture and much more. Flexibility in production is therefore more important than ever. For us, that means technology in a nutshell: maximum performance with maximum economy in all matters.

The Zeres 3 F Series is available in clamping forces from 150 to 450 Tonnes.

PRECISE INTELLIGENT INTERACTIVE

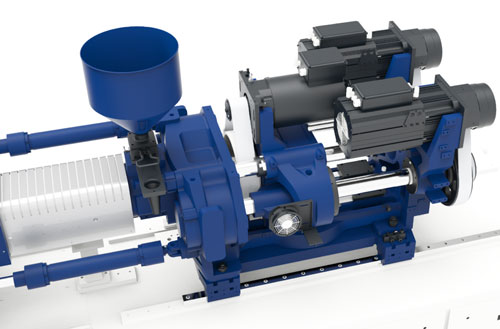

The Zhafir Zeres series with integrated servo hydraulics stands for precision, process stability and independent parallel movements throughout the cycle. Servo-electric drives ensure extremely high dynamics in the injection, metering and tool movements. The ZE-F variant (the F stands for “Fast”) offers an outstanding price-performance ratio in the area of high-speed applications.

DOWNLOAD BROCHURES

Electric

Yes

Sigmatec

Clamping Force

150 – 450t

Tie Bar Distance

820 x 820mm

Shot Volume

173 – 1,077cm³

DISCOVER ZHAFIR ZERES 3 F SERIES

KEY DATA

- From 1500 to 4500 kN

- Modular injection units

- L / D 25: 1 plasticizing unit

- Injection speed up to 350 mm / s

HIGHLIGHTS

- Customized electric & servo-hydraulic drives

- New generation of inverters for high precision and dynamics

- Precise repeatability during injection thanks to intelligent motion control

- Parallel movements as standard

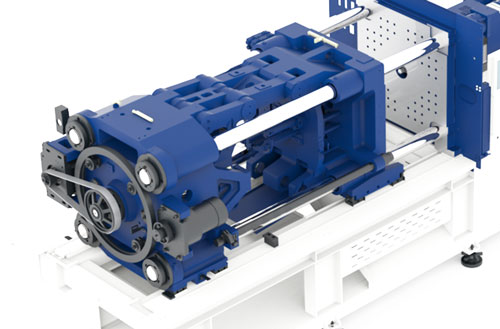

- Stable clamping unit with high rigidity (shortened toggle lever, linear guides)

- High stability even with heavy / large tools

- Square plate geometry for higher cavities

- Swiveling injection unit and easy maintenance

- Smooth integration of automation through Connectivity Plus

Linear guides to support the moving platen. Protective devices made of stainless steel for the trouble-free ejection of small parts.

A new generation of the clamping unit with linear guide and shortened toggle lever, low-friction and fast tool movement.

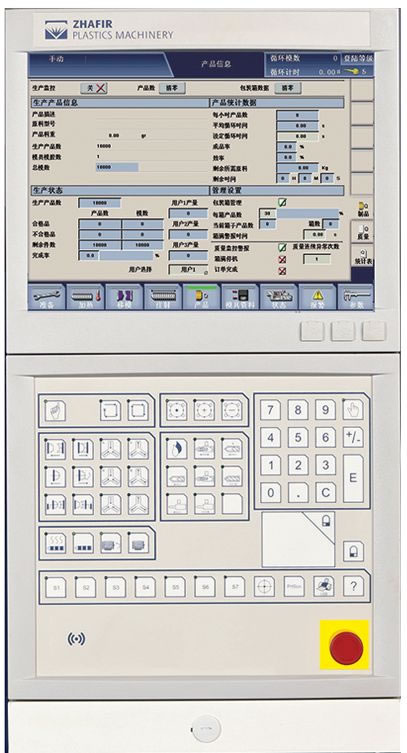

Software and Control

- 15-inch color touch LCD screen

- Three general-purpose USB interfaces

- Mould profile data memory (up to 200 sets)

- New performance for production monitoring

- User-friendly user interface

- Comprehensive software functions

- LED operation indicator

- Clear and simple button to re-layout

- Shortcut configuration for clear identification

- Multi-language available

- RFID card with password control for an easier factory management

Contact

Premier Moulding Machinery Ltd

Ladymead Business Park

Quainton

Aylesbury

Bucks

HP22 4AN

Sales : 01296 655555

Service : 01296 653037

Send your enquiry today

sales@haitian.co.uk

What 3 Words ///streaks.trustees.nightlife

Switch to Electric?

Contact us today to receive our FREE cost analysis package to help you understand why so many companies are switching to Electric...

Latest News

9000 Linked in followers

We are delighted that as our success in the UK has grown, so has the number of our linkedin...

Haitian China visit new Technical Centre

Our friends and colleagues visit our new Technical Centre in Aylesbury, From left to right...