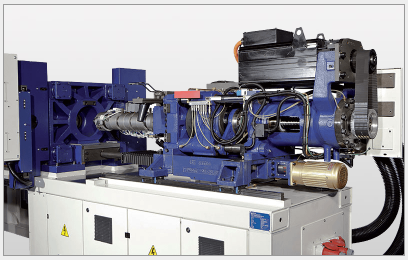

Zhafir VENUS 2 Series

SECOND GENERATION OF OUR ALL ELECTRIC SOLUTION

With 6,000 machines sold worldwide so far since its introduction in 2007, the Venus Series is established also in Europe as a trendsetter that has an outstanding price-performance ratio.

With high acceleration and precision, modular injection units at various performance levels up to 500 mm/s. Its energy-savings drive gives the processor the possibility to reduce the energy costs by up to 70 % in comparison to hydraulic machines.

DOWNLOAD BROCHURE

All Electric

Yes

Sigmatec

Clamping Force

40 – 800t

1,080 x 1,080 mm

12 – 2,354 cm³

DISCOVER ZHAFIR VENUS SERIES

Injection Unit

High Acceleration and Speed

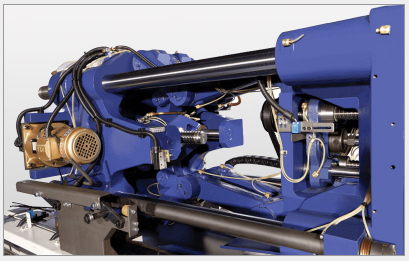

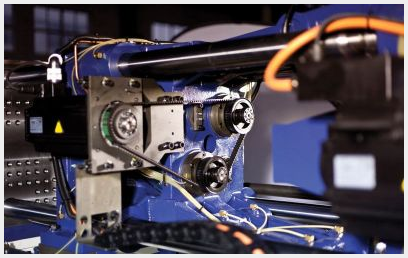

The New Design Of The Injection Unit

The injection unit is more compact. A reduction of single components bring more stability and dynamics in the injection movement.

For example, the high-speed injection unit 210h reaches an efficient reaction of 35 ms from 0 to 350 mm/s.

Easy Maintenance

Easy Maintenance

The Swiveling Injection Unit

The unit allows quick change of screw and plastification components and shorter set up times. Allowing easy replacement of the modules and easy accessibility for cleaning and maintenance.

Energy Saving

Energy Saving

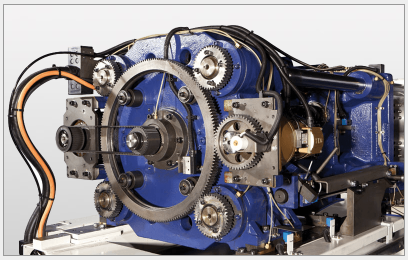

Matching Of The Servo Motor

Matching of the servo motor and servo drive enables further improvement of the acceleration rate and utilisation of renewable resources, realising energy saving.

More Stability

More Stability

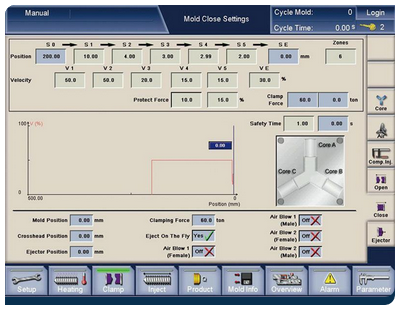

Optimised Toggle Design

The redesigned 5-point-toggle-system increases the platen intensity, reduces platen inertia and joint stress. More efficiency and a smooth operation performance through optimisation of the mechanical structure. This delivers an optimised speed curve and reduced dry cycle times.

Fast Setup Times

Fast Setup Times

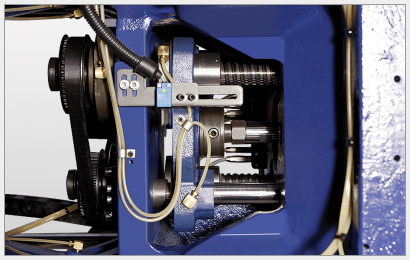

The Encoder On Mould Height Adjustment

This decreases the setup times during mould changes.

Quick Mould Removal

Quick Mould Removal

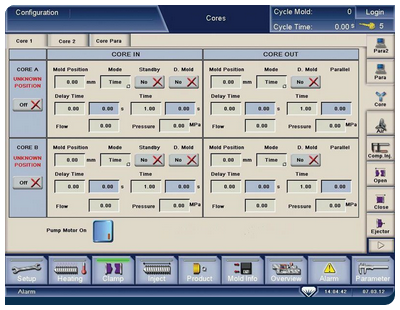

The Ejector Rapid Release Coupling

This decreases the mould change times. The ejector rapid release coupling allows an ejector bolt connection within 30 s.

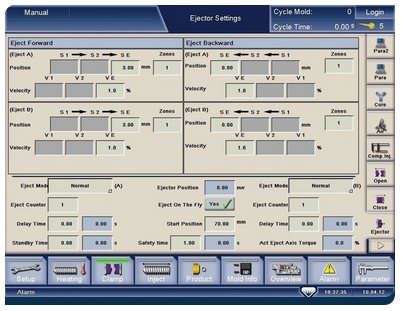

High Precision

Longer Lifetime

The Twin Ball Screw

The twin ball screw improves the ejector balance speed and torque for high acceleration and precision.

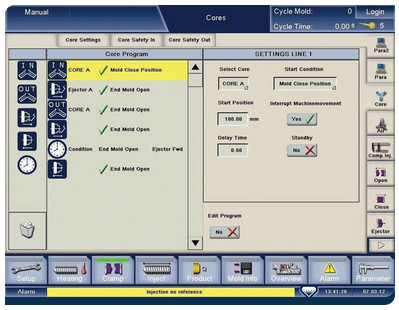

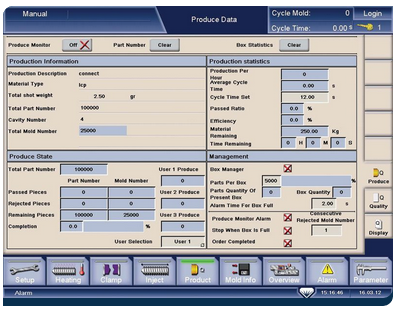

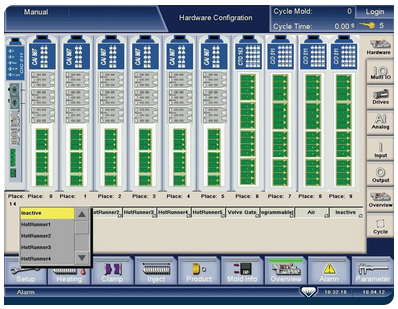

Control Technology

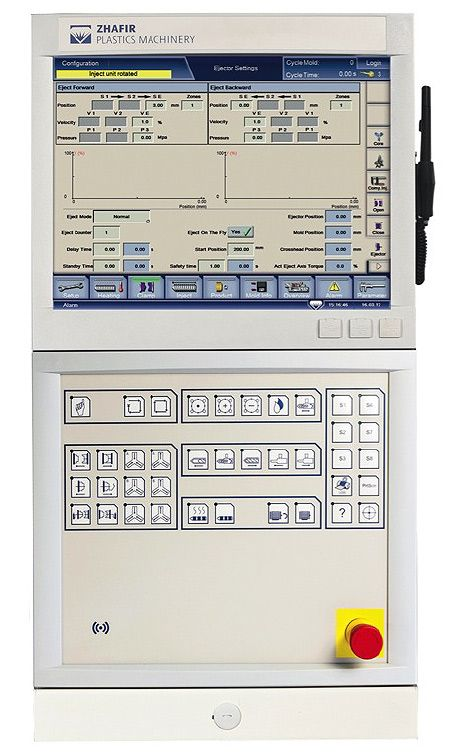

Latest Control Technology From Sigmatek

- 15-inch color touch LCD screen

- Three general-purpose USB interfaces

- RFID card with password control for an easier factory management

- Digital input and physical keyboard

- Pointer-touchpad

- LED operation indicator

- Clear and simple button to re-layout

- Shortcut configuration for clear identification

- 16 languages in standard

Contact

Premier Moulding Machinery Ltd

Ladymead Business Park

Quainton

Aylesbury

Bucks

HP22 4AN

Sales : 01296 655555

Service : 01296 653037

Send your enquiry today

sales@haitian.co.uk

What 3 Words ///streaks.trustees.nightlife

Switch to Electric?

Contact us today to receive our FREE cost analysis package to help you understand why so many companies are switching to Electric...

Latest News

9000 Linked in followers

We are delighted that as our success in the UK has grown, so has the number of our linkedin...

Haitian China visit new Technical Centre

Our friends and colleagues visit our new Technical Centre in Aylesbury, From left to right...