HAITIAN JUPITER 3 SERIES

ENERGY SAVING TWO PLATEN MACHINE

3rd GENERATION TECHNOLOGY

The Haitian JUPITER 3 Series (JU), has been developed based on Haitian’s extensive experience in sustainable research and development of two-platen solutions over the past two decades. Significant improvements over the previous machine generation provides more advantages for many different moulding applications.

The new design incorporates additional functions and user benefits which greatly enhance the machine performance and moulded part quality. With flexible clamping unit to injection unit combinations, the machine can be tailored to specific or general moulding applications.

As a product with Technology to the Point, the new generation of the Haitian JU provides a wide variety of combination possibilities in a compact footprint, which maximises the usable space of the factory for the customers’ benefit.

From large parts such as rubbish bins and logistics boxes, to high-precision automotive parts, high-tech parts with high surface quality, such as white goods, the JU 3 Series provides the best solution for customers.

DOWNLOAD BROCHURES

Drive Technology

Servo hydraulic

Control System

Keba

Clamp Force

450 – 6,600t

Clamping System

2 Platen

Tie Bar Distance

2,400 x 2,000 mm

Shot Volume

792 – 80,170cm³

DISCOVER HAITIAN JUPITER SERIES

Compact Design

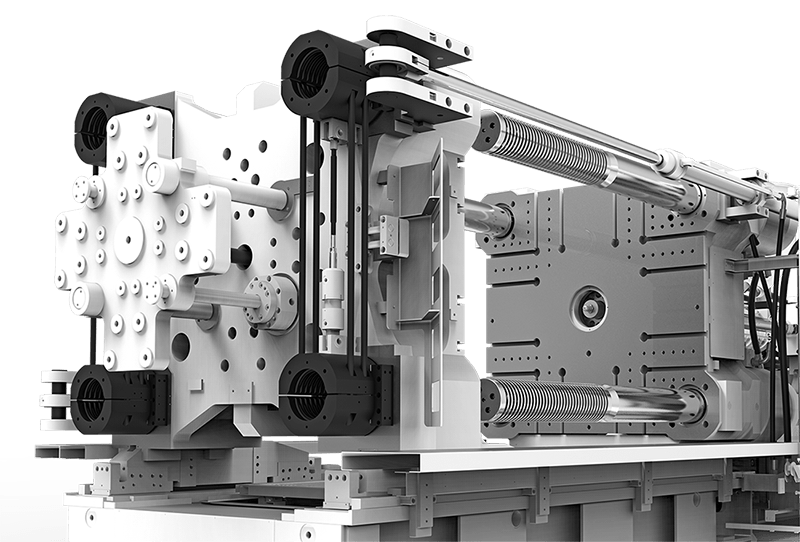

Compact Two-Platen Design

with Twin Cylinder Design

The structure of clamping unit is more reasonable because of the tie bar suspension structure which reduces the load.

Clamping Structure

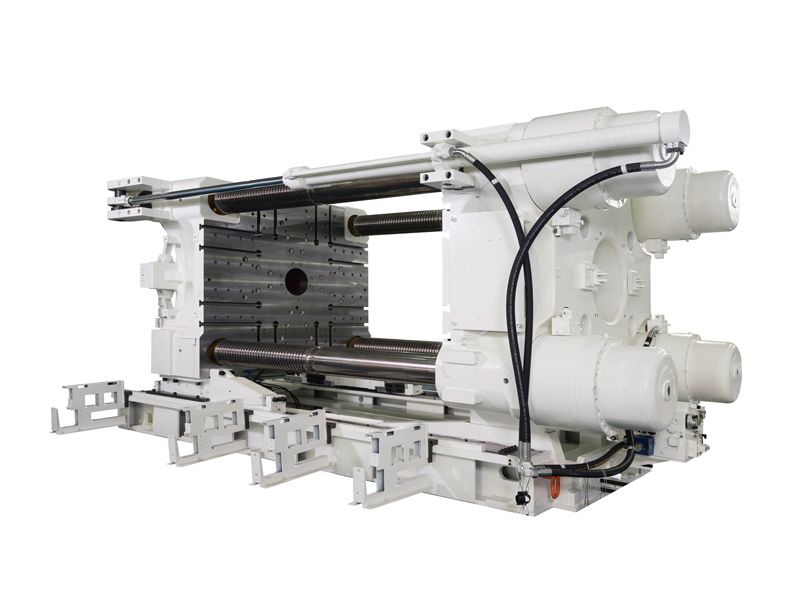

Fast & Balanced Clamping Structure

Optimised Design of Clamping Cylinders

Four short stroke clamping cylinders for accurate mold height control with closed loop position feedback, ensures the mold is clamped with parallel movement.

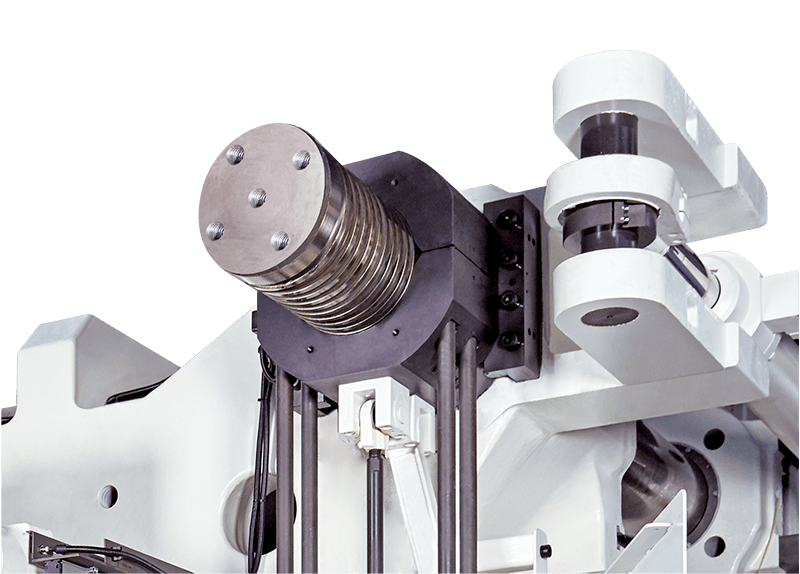

Nut Lock

Reliable Nut Lock Operation

Parallel lock nut operation ensures fast and accurate response.

Moving Platen

NEW Moving Platen Structure for Bigger Moulds

Large Moving Platen Supports

Rigidity during movement with increased mould weight loading. Reduced platen vertical movement for long core moulds.

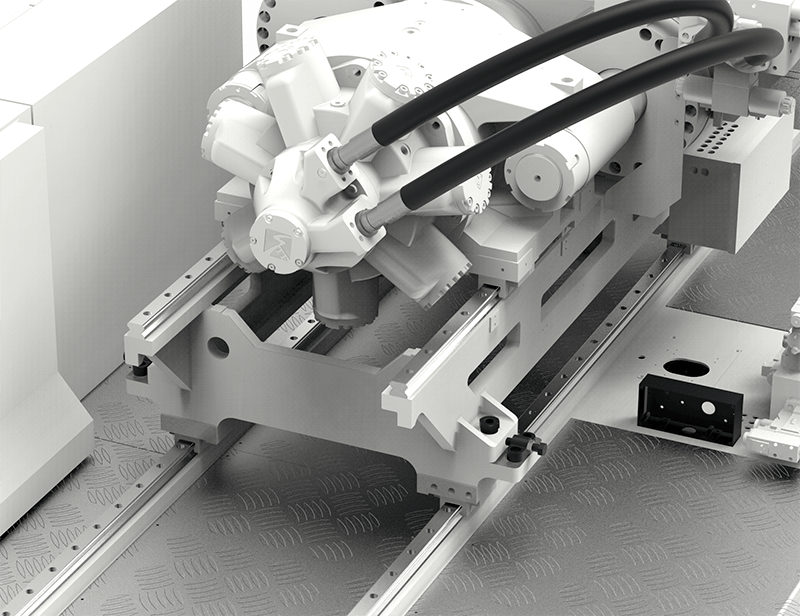

New Injection Unit

New Injection Unit

Low friction-high precision guiding mechanism for perfect screw guidance.

Energy Saving

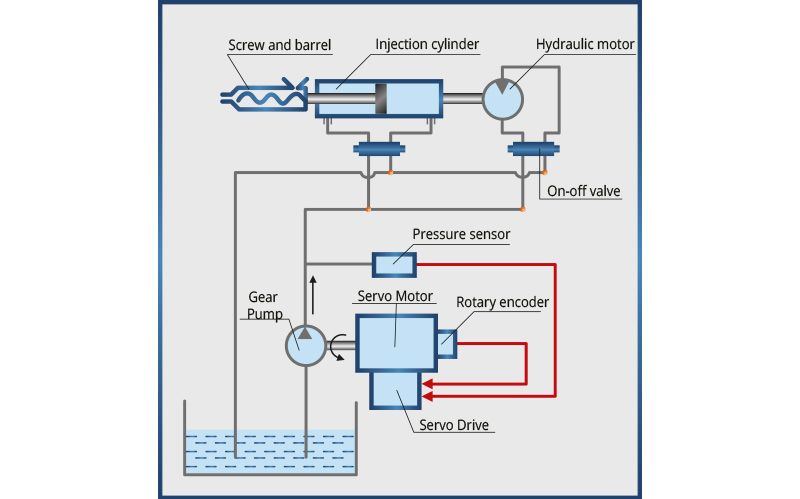

Energy Saving Drive System – Mars Technology

Patented Servo-Motor to Gear Pump Design

The direct drive connection between the servo-motor and the gear pump provides excellent drive torque giving maximum acceleration and deceleration speeds for all machine functions. The Jupiter II Series is also equipped with the innovative “Mars Technology”.

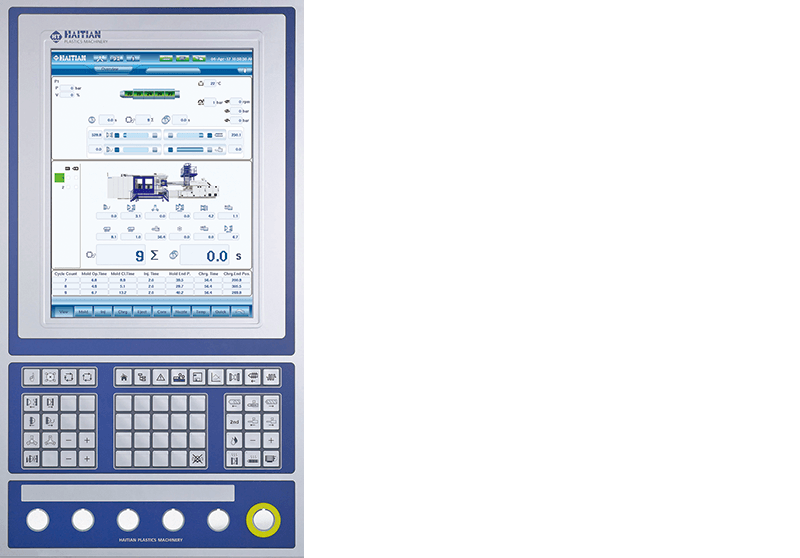

Control Technology

Software and Control

- High-performance KEBA or TECHMATION control

- Mould profile data memory

- New performance for production monitoring

- User-friendly user interface

- Comprehensive software functions

- Clear and simple button to re-layout

- Shortcut configuration for clear identification

- Multi-language available

Contact

Premier Moulding Machinery Ltd

Ladymead Business Park

Quainton

Aylesbury

Bucks

HP22 4AN

Sales : 01296 655555

Service : 01296 653037

Send your enquiry today

sales@haitian.co.uk

What 3 Words ///streaks.trustees.nightlife

Switch to Electric?

Contact us today to receive our FREE cost analysis package to help you understand why so many companies are switching to Electric...

Latest News

9000 Linked in followers

We are delighted that as our success in the UK has grown, so has the number of our linkedin...

Haitian China visit new Technical Centre

Our friends and colleagues visit our new Technical Centre in Aylesbury, From left to right...