HAITIAN MARS 3 PLUS SERIES

TECHNOLOGY TO THE POINT

The Haitian MARS Series has been on the market for over 10 years and continues to be the top of the line in servo hydraulic injection-molding technology – the world’s best-selling injection-molding machine. Since its market launch in 2006, more than 230,000 units of the MARS Series have been delivered.

The upgraded MARS – Mars 3 Plus – comes with many design improvements tailored for the European market. It has new motors, larger platens with increased tie bar clearance and new hardware to maximise energy efficiency while improving the precision.

DOWNLOAD BROCHURE

Servo hydraulic

Clamping Force

70 – 350t

Clamping System

Toggle, platen with linear guides

Shot Volume

50 – 1,078 cm³

DISCOVER HAITIAN MARS 3 Plus SERIES

Innovative Technology

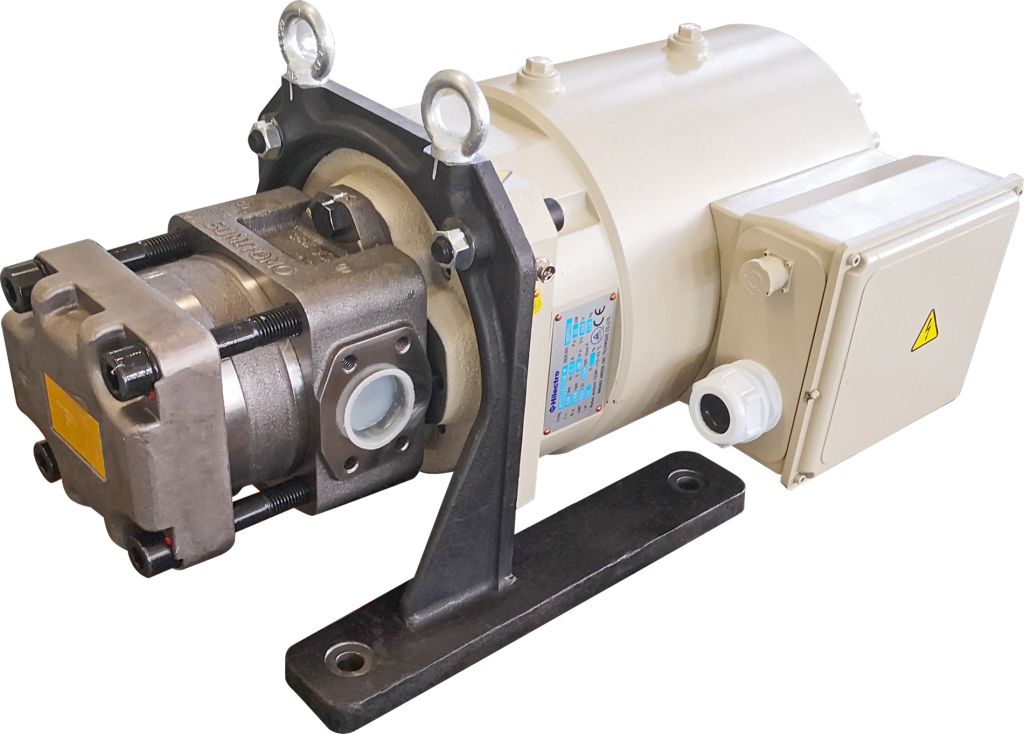

New high performance servo drive system

Innovative MARS Technology

The direct drive connection between the servo-motor and the gear pump provides excellent drive torque giving maximum acceleration and deceleration speeds for all machine functions.

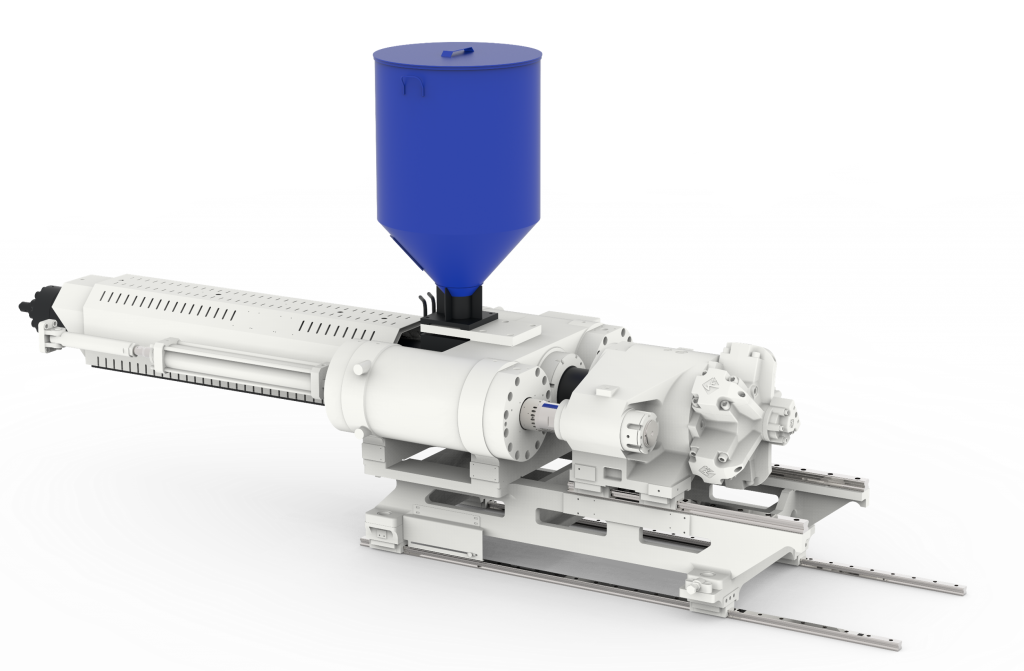

Injection Unit

High Performance Injection Unit

Linear guides on both carriage and injection give better acceleration and deceleration response times

and more precise back pressure control.

The swiveling injection unit comes as standard and gives a 30% time saving in screw replacement.

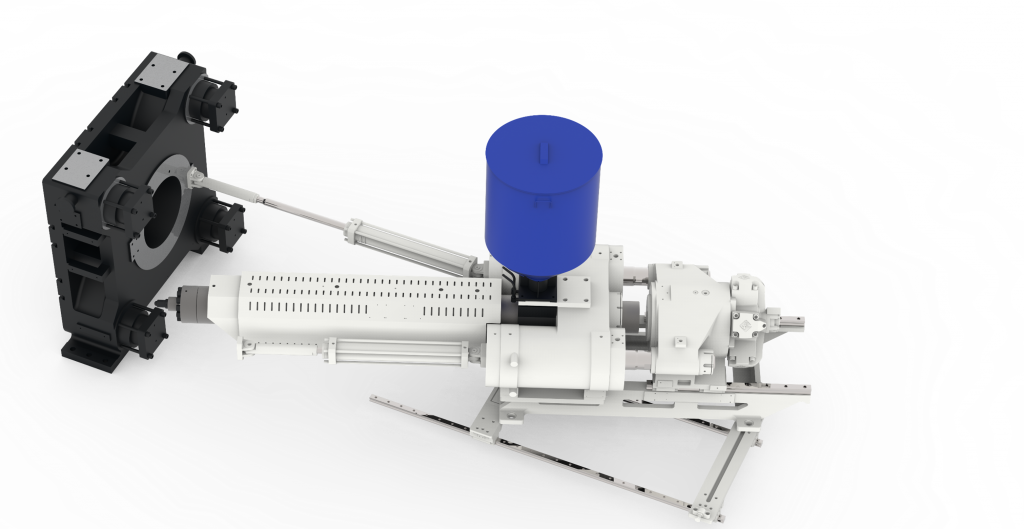

Clamping Unit

Clamping Unit

Redesigned Clamping

The bottom of the moving platen runs on linear guides which gives lower energy consumption and faster movements for reduced cycle times.

The top of the moving platen is contact less, this gives a cleaner moving platen with an oil free condition.

Proportional Control

Proportional control for the clamping unit

Gives higher precision of the clamp unit position

Proportional Control Technology

Proportional valve for the clamping unit offers faster mold opening and closing

Higher precision

Repeatability up to 0.5mm

Easy Entry for Tools

External Door

Easy access for tool loading

The moving door is external which gives easy access and the opening distance is increased.

There is no upper rail which means less height is needed for tool loading and it gives easy access for robots.

Open clamping base

Easy access for conveyors

The clamping base has an open style to make it easier to place conveyors under the machine.

Note : The above is the basement structure of MA2100III/plus and below, while the basement of MA2700III/plus and above is only open from the front.

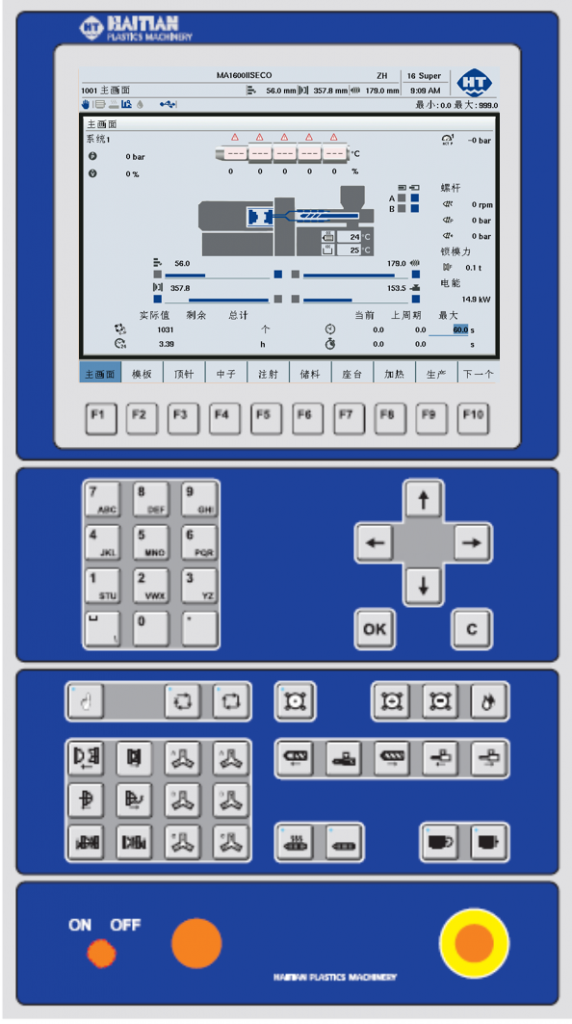

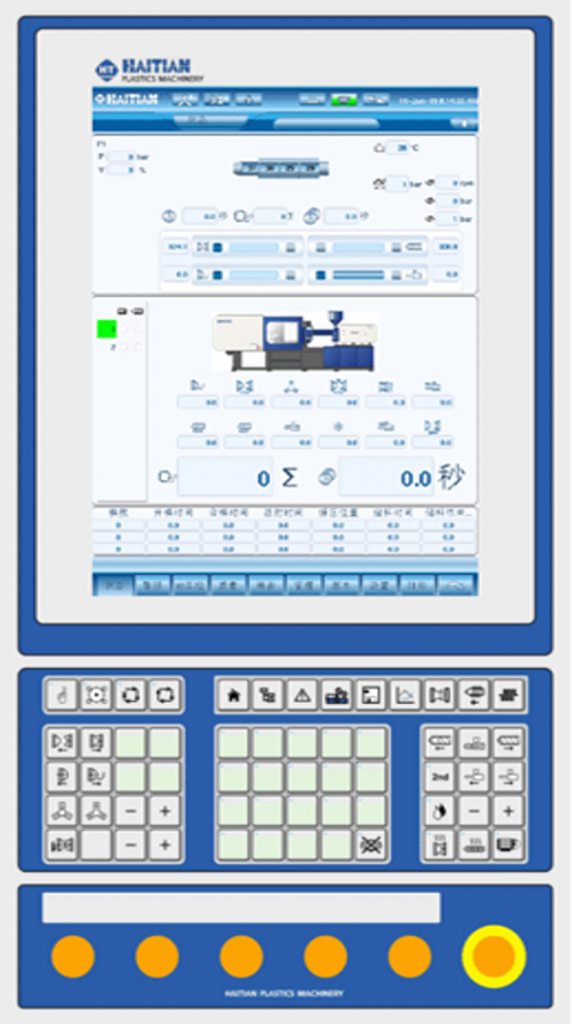

Control Technology

Software and Control

- High-performance KEBA control

- Mould profile data memory

- New performance for production monitoring

- User-friendly user interface

- Comprehensive software functions

- Clear and simple button to re-layout

- Shortcut configuration for clear identification

- Multi-language available

Keba 1180 – 12 inch screen as standard

Keba 2285 – 15″ touch screen as an option

Contact

Premier Moulding Machinery Ltd

Ladymead Business Park

Quainton

Aylesbury

Bucks

HP22 4AN

Sales : 01296 655555

Service : 01296 653037

Send your enquiry today

sales@haitian.co.uk

What 3 Words ///streaks.trustees.nightlife

Switch to Electric?

Contact us today to receive our FREE cost analysis package to help you understand why so many companies are switching to Electric...

Latest News

9000 Linked in followers

We are delighted that as our success in the UK has grown, so has the number of our linkedin...

Haitian China visit new Technical Centre

Our friends and colleagues visit our new Technical Centre in Aylesbury, From left to right...