HAITIAN MARS 2s SERIES

TECHNOLOGY TO THE POINT

The Haitian MARS Series has been on the market for over 10 years and continues to be the top of the line in servo hydraulic injection-molding technology – the world’s best-selling injection-molding machine. Since its market launch in 2006, more than 230,000 units of the MARS Series have been delivered.

The upgraded MARS – so called “2s“ – comes with a lot of design improvements, which provides more reliable hardware to maximise the energy efficiency while improving the precision. The common design enables Haitian Plastics Machinery to deliver 30.000 machines and more per year in a short delivery time.

DOWNLOAD BROCHURE

Servo hydraulic

Clamping Force

60 – 1,000t

5 point toggle

50 – 6,769 cm³

DISCOVER HAITIAN MARS 2s SERIES

Innovative Technology

Patented Servo-Motor to gearpump design

Innovative MARS Technology

The direct drive connection between the servo-motor and the gear pump provides excellent drive torque giving maximum acceleration and deceleration speeds for all machine functions. The JUPITER 2 Series is also equipped with the innovative “MARS Technology”.

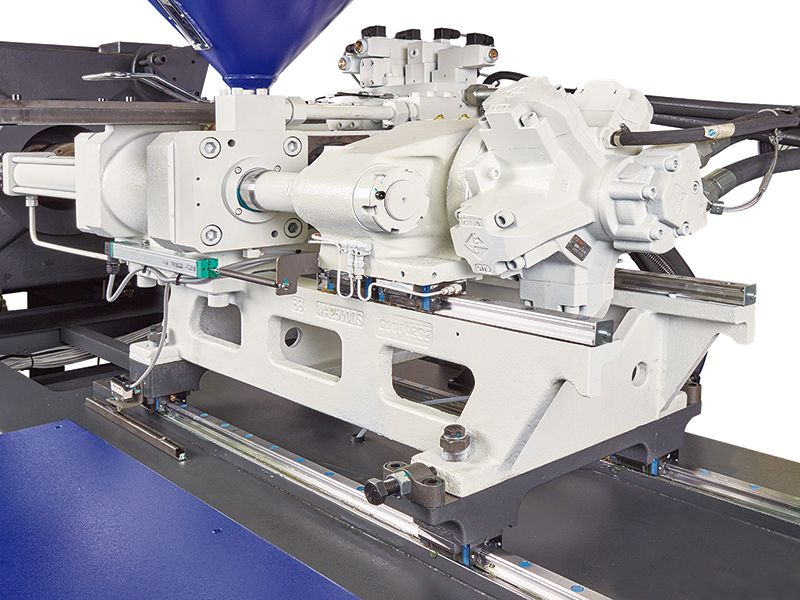

Injection Unit

High Performance Injection Unit

The rigid one piece injection base supports the common slide rail for injection and screw movements, reducing stress and increasing movement precision. The balanced twin injection cylinders apply equal force to the screw during injection.

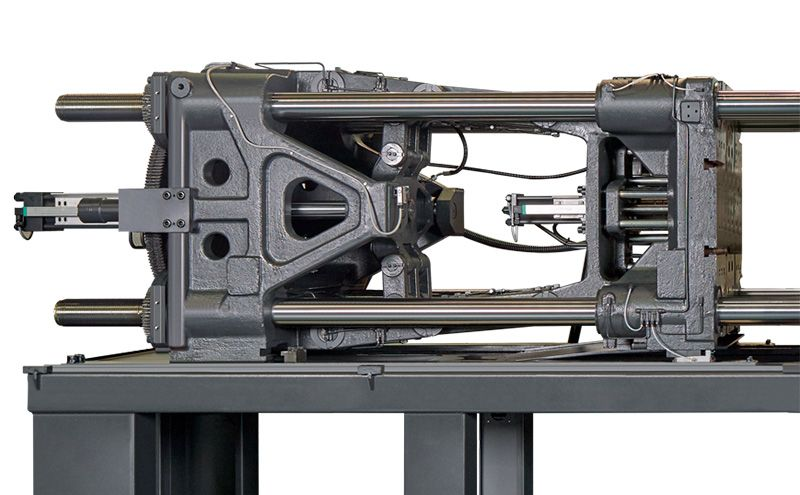

Clamping Unit

Clamping Unit

Redesigned Toggle Kinematics

Provides lower energy consumption and faster movements for reduced cycle times. The redesigned toggle kinematics for higher efficiency and lower energy consumption for small and large machines. The redesigned clamping unit provides lower platen stress and higher mould force stability, reducing mould wear and improving moulded product stability.

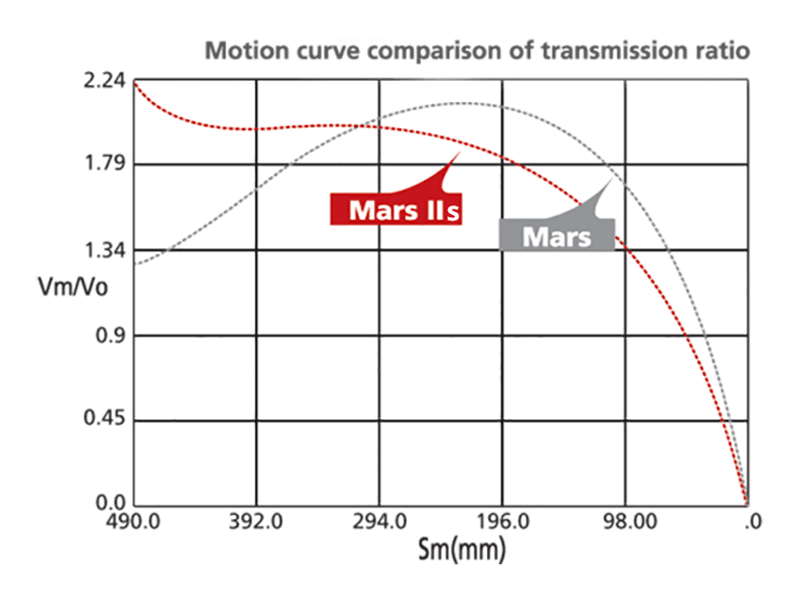

Faster Clamping

Faster Clamping Movements

Reduced Dry Cycle

Due to a new toggle design with optimised kinematics.

Graphic shows an example of 200-tonne clamping unit

Vm: Moving speed of movable platen

Vo: Moving speed of oil cylinder

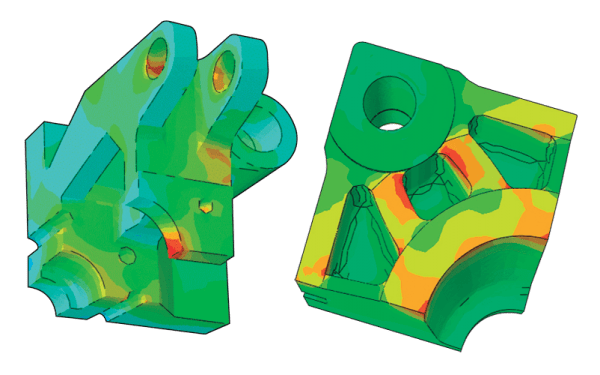

High Rigidity

High Rigidity

Optimised Platen Design Using FEA

Fixed platen with centralised force loading and less platen flexing. The redesigned moving platen provides centralised force distribution from the toggle system to the mould.

The result: higher rigidity and stability.

Longer Lifetime

Longer Lifetime

Providing better lubrication and lower lubrication consumption. A smooth operation leads to longer lifetime of the clamp, dramatically reducing maintenance requirements.

Control Technology

Software and Control

- High-performance KEBA control

- Mould profile data memory

- New performance for production monitoring

- User-friendly user interface

- Comprehensive software functions

- Clear and simple button to re-layout

- Shortcut configuration for clear identification

- Multi-language available

Contact

Premier Moulding Machinery Ltd

Ladymead Business Park

Quainton

Aylesbury

Bucks

HP22 4AN

Sales : 01296 655555

Service : 01296 653037

Send your enquiry today

sales@haitian.co.uk

What 3 Words ///streaks.trustees.nightlife

Switch to Electric?

Contact us today to receive our FREE cost analysis package to help you understand why so many companies are switching to Electric...

Latest News

9000 Linked in followers

We are delighted that as our success in the UK has grown, so has the number of our linkedin...

Haitian China visit new Technical Centre

Our friends and colleagues visit our new Technical Centre in Aylesbury, From left to right...